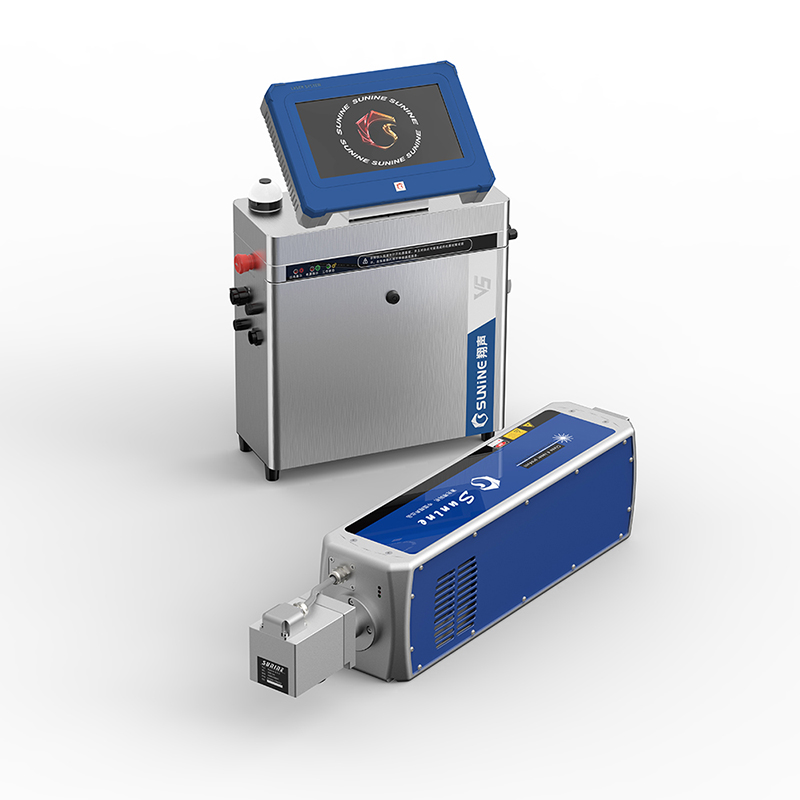

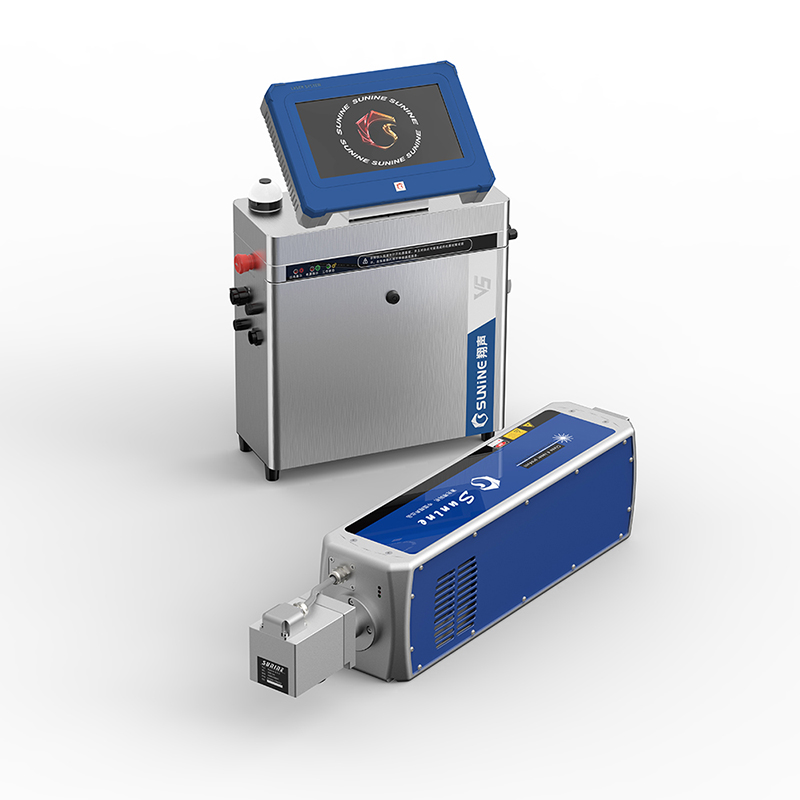

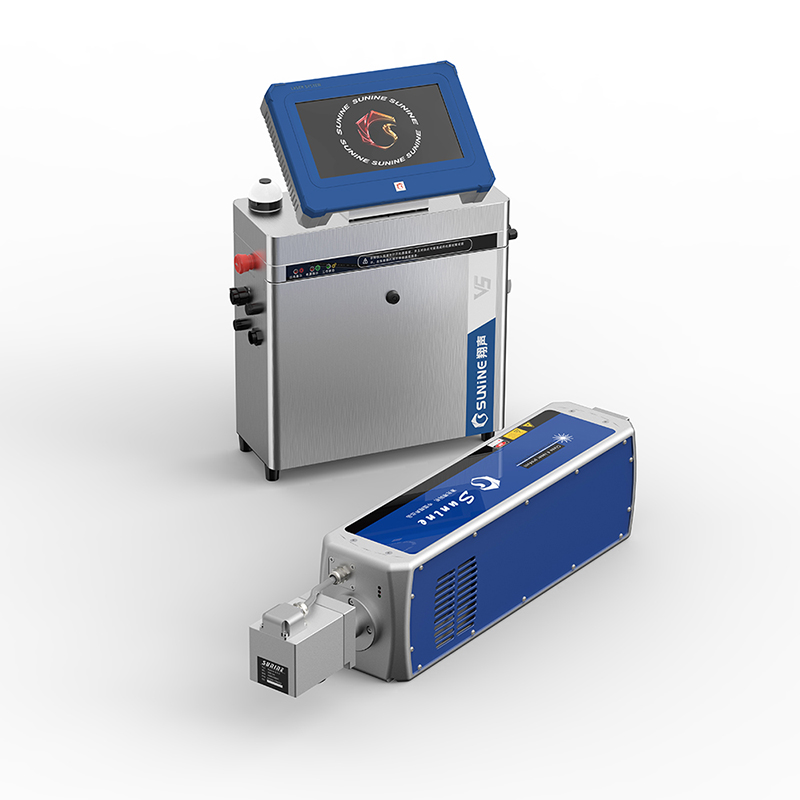

Sunine V310C/V320C/V330C 30W CO2 Laser Marking Machine

CO2 coding lasers are widely applied in production lines. 30W CO2 laser marking machines offer numerous advantages:

Great stability and high precision with intelligent circuit control.

Small size and unique design for easy installation in narrow spaces.

1.Non-stop 24-hour operation for high-efficiency product coding.

2. Low maintenance cost and no need for ink, ensuring clear and indelible marking.

3. Long lifetime with no need for consumable parts, solvents, or cleaning agents.

4. Versatile suitability for various materials, including cardboard, paper, wood, plastics, ceramics, glass, and more.

Long-Term Operation Stability

Sophisticated parts for machine,say no to substandard products

Power-on and ready-to-use, zeromaintenance cost

Self-developed software ensuresstable performance without any faults

Born For Efficiency

Draw line speed up to 12000mm/s

Standard and customizedcommunication protocols

High performance self-developedsmart chip set can quickly process huge data and complex graphics.

Easy-To-Operate

Smart touch screen panel

System operation is easy to use

Support various languages,one-button marking

Capabilityof Integration

Light-weightedbody made of high-density materials

High-transmittedfused silica field lens ensures high stability

Variousworking distances are available to adapt to all kinds of productionenvironments, making production line integration more flexible

Model | V310C | V320C | V330C |

Case/stand material | Anodized Aluminum (laser head)&stainless steel(control unit) | ||

Laser type | sealed metal RF CO2 laser source | ||

Output power | ≥30W | ||

Laser wavelength | 10.6μm | 10.2μm | 9.3μm |

Marking method | high precision 2D scanning method | ||

marking speed | ≤18000mm/s | ||

| power supply | 220V | ||

Operating system | Linux | ||

Cooling system | Air cooling system | ||

Type of marking line | Dot martix and vector format | ||

Reflector size | Standard:8.5mm | ||

Marking range | Standard:90mm×90mm, max to 450mm x450mm | ||

Positioning method | Red light positioning, auto focus | ||

Lines of marking | No limit within marking field | ||

control unit size | 403mmX383mmX160mm | ||

Fonts | English, Chinese, Spanish, Russian, Korean, Arabian etc. | ||

File format | BMP/DXF/HPGL/JPEG/PLT | ||

Bar code / QR code | CODE39/CODE128/code126/QR code/Z-code/DM code/Visual code, etc | ||

| Weight | 33KG | ||

10.6µm wavelength getswell absorbed in applications that process materials ranging from thin paper tocardboard packaging. Extremely good print results are also achieved on glass products. This wavelength is the most common one available with CO2 lasers and perfectly suits the majority of packaging applications.

10.2µm wavelength isideally suited to marking on thin films and any types of packaging foils. Bestresults can be expected on painted films and foils with a thin ink layer ontop. Packaging materials which absorb this wavelength very well and thereforegenerate the best CO2-Laser print quality are PE, HDPE,LDPE, PP, OPP, OPA, PA, PMMA, POM, PUR, ABS and PVC.

9.3µm wavelength perfectlymatches for the head absorption of plastics like PET (PolyethyleneTerephthalate), allows marking on plastic surfaces by smoothly melting thesurface layer without creating pinholes or cracking the inner structure. Thisis the ideal solution for the family of polyesters of thermoplastic resins. PET is wide-spreading in the beverage industry and is mostly used for producingbottles.